Magnetic Beltless Slide Conveyors Storch Material Handling |

Magnetic Beltless Slide Conveyors

|

|

|

|

||

| Storch Beltless Magnetic Slide Conveyor |

Features

|

Benefits

|

|

Stamping Parts Transfer |

Machining Chips & Scrap Removal from Coolant |

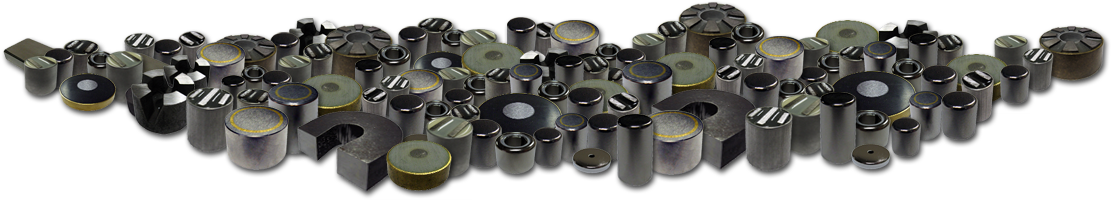

| Storch Beltless Magnetic Slide Conveyors provide Industrial Automation conveying hot, cold, wet, oily or dry ferrous materials virtually anywhere trouble-free conveying is required. Magnetic Beltless Conveyors, with permanent and powerful ceramic or rare earth magnets, chain driven under a non-moving slide plate, are ideal for conveying small turnings, stampings and small assembly components as well as scrap such as punch-outs, trim stock and chips.Whether your need is for light duty jobs or heavy work loads, the four series of Storch Magnetic Beltless Slide Conveyors are designed with all moving parts completely enclosed so there’s nothing to jam, become contaminated or wear. And, being beltless magnetic conveyor, with no external moving parts means these conveyors are safe for employees.Beltless Magnetic Slide Conveyors from Storch can be configured with perforated side guides, auxiliary collection tanks and vertical rises to efficiently and economically separate parts or scrap from oils and coolant. This results in simpler coolant reclamation with less wear and tear on filtering equipment and machinery. Plus, dryer chips means more value and less danger to the environment. |

Why Buy Storch Beltless Magnetic Slide Conveyors? |

| Storch Beltless Mag-Slide Conveyors are custom built to order, using your sizing specifications and our 35+ years of application and Manufacturing experience. Place an order and you’ll have an approval drawing that you can lay into your floor plan to review prior to manufacturing.Storch designs each and every Beltless Magnetic Conveyor using AutoCAD computer software, and we cut all sheet metal components using our own CNC Laser Cutter.All Flat Laser cut sheet metal components and those requiring bending are bent using our NC Press Brake. This type of manufacturing means every single detail from re-buildable bolt in tracking to a chain guard, support leg or motor mounts can be reproduced using your provided serial number within a few thousands tolerance of the original. Damage will occur and Storch’s ability to react to quick replacement parts is second to none.… A new Magnetic Beltless Conveyor or replacement part is only a phone call away! |

How the Beltless Magnetic Slide Conveyor System Works |

|

| Typical Applications: CNC Machining Grinding & Lapping, CNC Turning, Vertical & Horizontal Milling, Light-Medium Gauge Metal Stamping, Cold Heading, Fasteners, Nuts, Bolts & Washers, Screws, Parts Feeding and Central Scrap Collection |

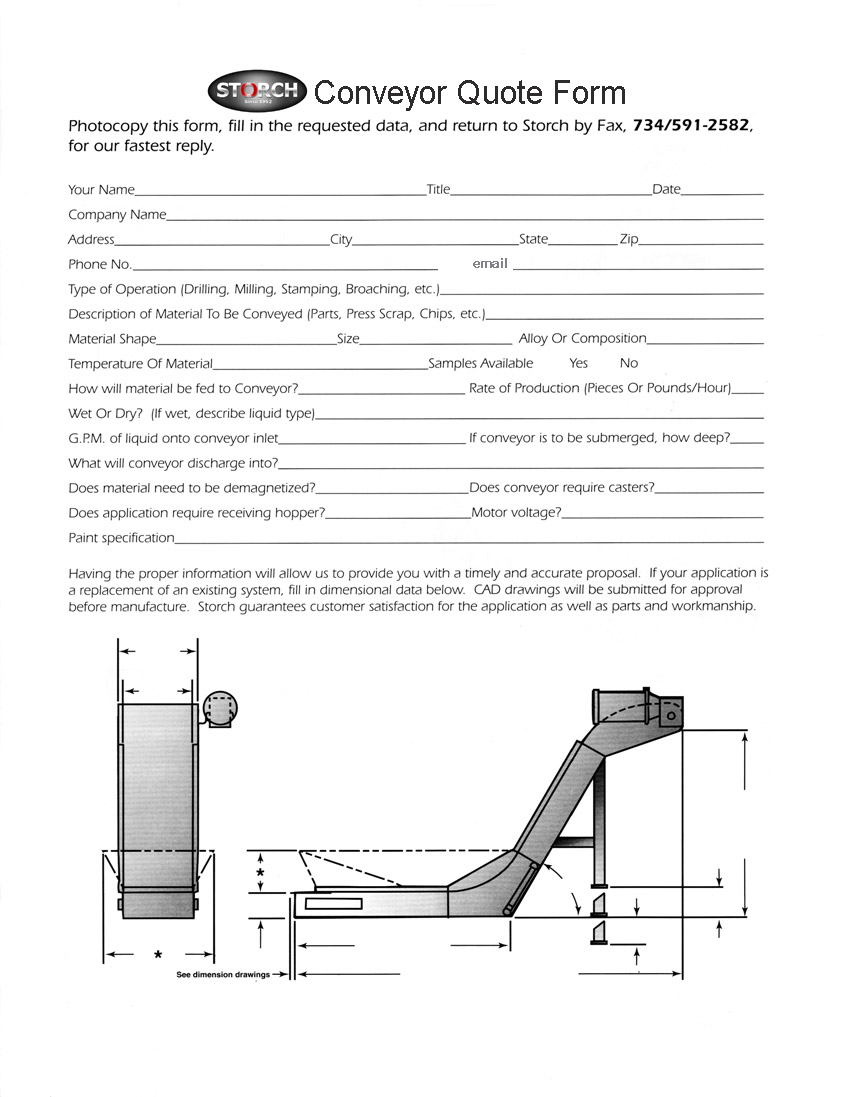

Please Click the forms below to view or print, fill-in and fax or email

|

|

Storch Magnetics has pre-engineered, ready-to-manufacture Magnetic Beltless Slide Conveyors

to fit the following Machining Centers:

| Daewoo | Doosan | Hyundai | Murata | Okuma | |

| ACE-V35 | QL-30H | SKT-300 | MW-200 | 2SP-V55 | |

| V-450-T | SKT-V5 | 2SP-V80 | |||

| V-550 | 2SV-25H | ||||

| V-740 | |||||

| V-850 |

People who visited this page also visited these Storch Material Handling pages:

Belt Conveyors – Magnetic

Belt Conveyors – Non Magnetic

Pneumatic Shaker – Air Quake

Magnetic Beltless Slide Conveyor