Request A Quote

For information or a quote, please contact us:

Toll Free: 800.959.0047 • Phone: 734.591.2200

Email: sales@storchmagnetics.com

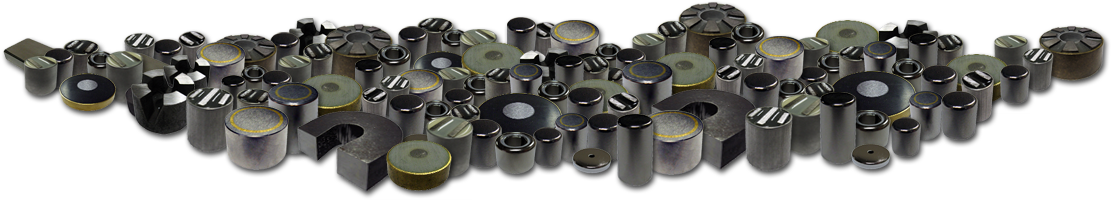

Steel Hinge Belt Conveyors

Storch Steel Hinge Belt Conveyors are versatile for cold heading, dies, machining, presses and parts handling operations. Ideal for many installations: single station, central collection and in-floor systems.Storch Steel Hinge Belt Conveyors are designed with either 1-1/2″ or 2-1/2″ pitch. The pitch is determined by the type of material to be conveyed and the size restraints of the application. Storch Steel Hinge Belt Conveyors are designed in-house to exceed the specifications of OEM supplied conveyors. From Heavy Duty replaceable tracking to oversized rollers on the belt; Storch has put together a winning combination that is dependable and price competitive.

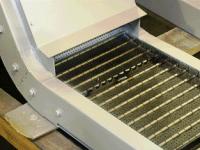

1-1/2″ Pitch Steel Hinge Belt Conveyors

Typical for small to medium parts, fasteners & scrap handling, and light to medium chip handling. Low profile applications can easily be accomplished on our 1-1/2″ pitch steel hinge belt conveyor with a standard low-profile 5″ tall frame.

Storch 1-1/2″ Pitch Steel Hinge Belt Conveyor

Features

- All conveyors engineered to meet your specifications

- Heavy duty drive train with integrated gear motors and slip-clutch overload protection

- Precision CNC Laser-cut & formed body and tracking

- Heavy Duty oversized rollers & 25% thicker belting for increased strength

- Simple, external belt tension adjustment take-ups

- Removable cover plates provide easy access for cleaning and maintenance

Benefits

- Convey ferrous and non-ferrous materials

- Replaceable tracking extends conveyor life

- Increase Productivity, Uptime & Profitability

- Increase chip and scrap value & reduce coolant loss

Typical Applications: CNC Machining, CNC Turning, Vertical & Horizontal Milling, Light-Medium Gauge Metal Stamping, Cold Heading, Parts Feeding, Central Scrap Collection

Belt Options: Smooth, Perforated, Pimpled, Pimpled-Perforated

Cleat Options: Plain, Serrated, Wiper

2-1/2″ Pitch Steel Hinge Belt Conveyors

Medium to large parts, fasteners & scrap handling, and medium to heavy chip handling transfers, along with applications that create stringers and bird’s-nests require a more heavy-duty designed Storch 2-1/2″ pitch steel hinge belt conveyor with a 9″ tall frame.Hinge belt components manufactured from heavy gauge, durable steels.

Storch 2-1/2″ Pitch Steel Hinge Belt Conveyor w/Open Discharge & Overhead Drive

Features

- All conveyors engineered to meet your specifications

- Heavy duty drive train with integrated gear motors and slip-clutch overload protection

- Precision CNC Laser-cut & formed body and tracking

- Heavy Duty fixtured & welded tracking

- Simple, external belt tension adjustment take-ups

- Removable cover plates provide easy access for cleaning and maintenance

Benefits

- Increase Productivity, Uptime & Profitability

- Increase chip and scrap value & reduce coolant loss

- Heavy duty construction = Longer life cycle & Higher ROI

Belt Options: Smooth, Perforated, Pimpled, Pimpled-Perforated, Import Bars

Typical Applications: CNC Machining, CNC Turning, Vertical & Horizontal Milling, Light-Medium Gauge Metal Stamping, Cold Heading, Parts Feeding, Central Scrap Collection

Cleat Options: Plain, Serrated, Wiper

Steel Hinge Belt Conveyor w/Open Discharge, Perforated Belt & Serrated Cleats

Steel Hinge Belt Conveyor w/Covered Incline, Perforated Belt & Serrated Cleats

For over 60 years Storch Magnetics has engineered and built quality equipment in-house. We are certain that you’ll be happy with this addition to our material handling line.

People who visited this page also visited these Storch Material Handling pages: