Magnetic Drum Separator Storch Metal Separation |

Magnetic Drum Separator

|

|

|

|

|

|

||

| Magnetic Drum Separator |

Features

|

Benefits

|

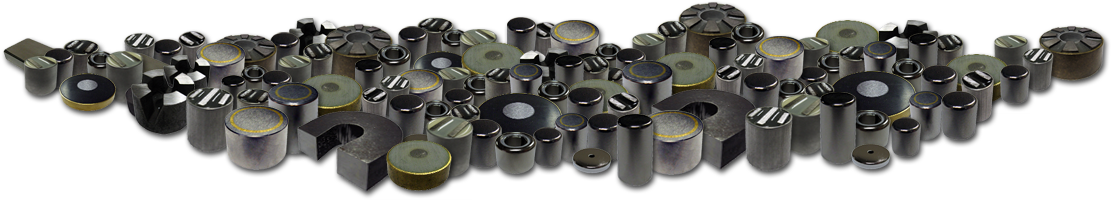

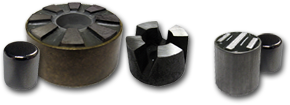

Magnetic Drum Separators & HousingsMaterial Handling Automation systems and Storch Self Cleaning Drum Magnets go hand in hand. Self Cleaning Drum Magnets allow for continuous metal recovery cleaning of metal fines, nuts, bolts, and miscellaneous tramp metals found in plastics, food/grain, chemical, pharmaceutical, foundry, mining, rock/concrete, and various bulk granular abrasive flows. Storch self cleaning drum magnets feature automatic cleaning, eliminating down time to your process. Proper application of drum magnets are an economical solution to solve product contamination problems. |

|

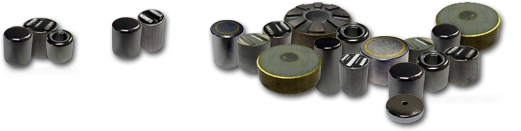

Drum Magnet Separators without housings

- Storch Standard 180 half moon magnet element provides outstanding value.

- High performance Strontium Ferrite permanent magnet ceramic 5 & 8A.

- Rare Earth Neodymium (NdFeB) magnet drums as needed.

- Optimized Magnetic Circuitry/Assembly to meet your product flow.

- Magnet Material meets or exceeds IMA/MMPA standards.

- Rugged Stainless Industrial Magnetic Separator system for extended service.

Drum Magnet Separators with housings

Drum Magnet Separators with housings

Storch various powerful stationary permanent magnet circuits/assembly enclosed in a 304 Stainless Steel Drum is the heart of the unit. Tramp iron is attracted to the rotating drum, Storch cleats provide additional tramp metal movement past magnetic field; cleaned materials flows through the first clean exit chute, while magnetically contaminated material is carried over to the second exit chute where ferrous is discharged from the magnet and drum.

- Incorporating the Storch Drum Magnet separator features

- Storch Magnet Drum housed in either 11 gauge mild or stainless steel

People who visited this page also visited these Storch Metal Separation pages:

Magnetic Drum Separator

Drawer Magnets

Plate Magnets – Ceramic